4 Remote Video Inspection Platforms for Factory Machinery

Are you leveraging every possible tool to maximize the effectiveness of your remote inspections? Conducting a practical remote inspection of factory machinery involves a lot more than talking your client through the process on the phone - and the consequences of conducting insufficient remote video inspections for industrial and manufacturing can be both costly and dangerous.

To achieve remote inspection mastery, you must invest in results-driven processes and techniques. Finding the right approach can deliver significant value to your customers, helping them to ensure that their machinery equipment is working properly, keeping both inspectors and clients safe.

So what are the best remote inspection platforms for 2021? This post will examine four different types of tools on the market today that may assist you with your remote inspections. This information will help you understand the available tools and their use-cases so you can make the best decision when it comes to implementing a remote inspection tool for your business.

4 Amazing Remote Video Inspection Platforms for Factory Machinery

You may be asking: Why conduct inspections remotely? Isn’t it easier and more effective to simply send an inspector on-site to examine factory machinery? Though in-person inspections were long considered the default method, remote video inspections are safer, more cost-effective, and more reliable than in-person inspections.

Other benefits of remote video inspections include saving time and money by allowing inspectors to dial into remote sessions rather than traveling to a client site. During the pandemic of the past few years, remote work has been safer for many reasons. Factory machinery also has dangerous aspects that can be hazardous - or nearly impossible - to inspect manually. Additionally, the stored footage from remote video inspections makes it easier to reference past inspections, find patterns, and ensure that you are performing quality inspections every time.

The Blitzz platform provides an effective, simple-to-use interface for remote inspections. If you are interested in learning more, schedule a demo of Blitzz today! Now, let’s dive into some of the remote video inspection options available today.

1. Unmanned Aerial Vehicles (UAV)

Unmanned Aerial Vehicles, or UAVs, are more commonly referred to as drones. Drones are small flying devices equipped with cameras that are used everywhere from Hollywood films to, you guessed it, inspection of machinery.

Inspectors use UAVs to examine pieces of equipment and machinery in high locations that are not easily accessible. One of the benefits of using UAVs for inspections is that it prevents people from traveling to these high-up, dangerous areas.

Leveraging UAVs for machinery inspections can also save you a significant amount of time and money. To inspect these areas manually, you would need to erect scaffolding. Bypassing the erection of this scaffolding can save you dozens of hours and, in some cases, tens of thousands of dollars.

UAVs are also capable of creating reliable inspection records. A digital copy of all the audits a given drone has performed can be stored and referenced as needed.

But drones are not appropriate for all types of inspections. The drone itself can be expensive to obtain and operate. If the factory machinery in question is accessible from the ground or would not require scaffolding to inspect, investing in a drone for inspection may be a waste of resources.

2. Remotely Operated Vehicles (ROV)

Remote Operated Vehicles (ROVs) are generally used for underwater inspections. These devices are submerged to inspect underwater pipelines and more. The benefit of using an ROV for this type of inspection is apparent: many of the machines examined by ROVs would not only be expensive but impossible to investigate manually.

ROVs can transmit video footage and environmental readings, such as depth and pressure, to the operator. When considering machinery located deep underwater, these readings can be vital elements of the inspection report.

In addition to inspecting underwater machinery, ROVs are also used to survey natural habitats and conduct exploratory environmental surveys. Most ROVs are safe for use in marine protected areas and will not disturb any wildlife that has made a home in the inspected area.

Much like the UAVs discussed above, footage from ROV inspections is also recorded and maintained digitally, meaning that you can examine the archived footage later on if needed.

A downside to ROV inspections is that there is only one main use-case: Underwater inspections. Most locations on land can be reached on foot or with a UAV more quickly than with a remote vehicle, making ROVs somewhat obsolete on dry land.

3. Fixed Devices

Fixed devices are also known as static equipment. These can refer to gauges and sensors that provide readings and cameras placed in key locations to allow for easy remote reference. This type of device can be used in most settings and is particularly useful if you have a specific part of a machine you know needs regular inspection.

These types of devices are most helpful in alerting maintenance staff of a problem with the machinery. A particular sensor reading may trigger an alarm, for example.

One benefit of using fixed devices for inspection is that there are not a lot of regular costs associated with maintaining these devices. Once they are placed and operational, they can be left alone and referenced until their life cycle expires, or you must address an unexpected maintenance issue.

An obvious downside of fixed devices is that they are, by definition, fixed. There isn’t a lot of flexibility with the use of fixed devices. If there is an issue with a part of the machinery not visible to the device, it could be missed in inspection.

4. Mobile Devices

The last type of device you might want to consider for your factory machinery inspections are mobile devices. Mobile remote inspection tools allow an inspector to communicate with a contact on-site through a cell phone or tablet or even smart glasses to enable the person on-site to have his or her hands free. The contact can then use the camera on their mobile device to walk the inspector through the machinery being inspected.

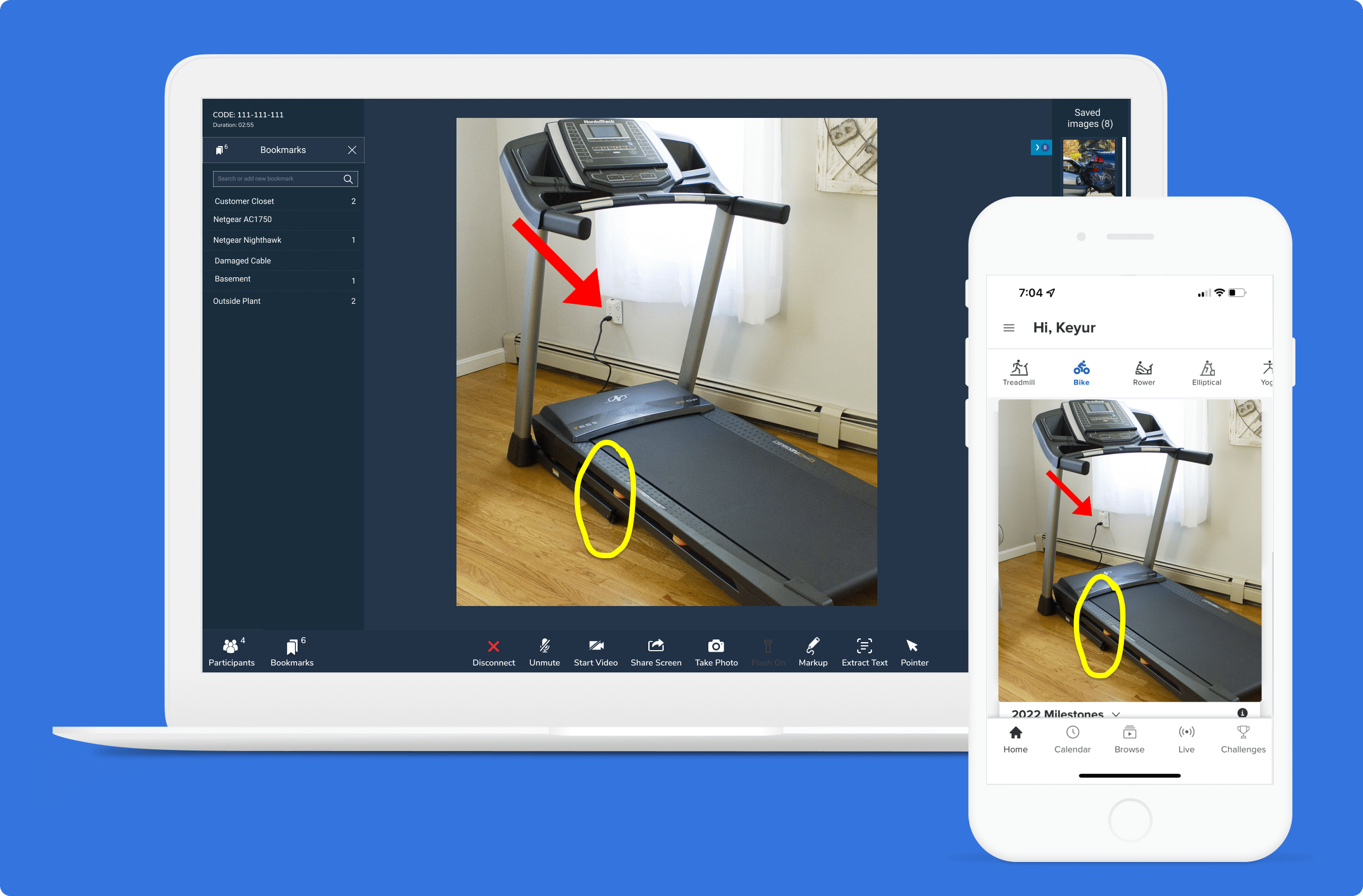

Some mobile inspection tools, like Blitzz, incorporate augmented reality (AR) features in their platform. These features allow the inspector to interact with the video image the site contact is sharing in real-time, drawing attention to certain screen areas, or collaborating using the live video pointer.

Mobile device tools are beneficial for use in remote video inspections because they are both cost-effective and convenient. Unlike the other three platforms listed above, mobile remote inspection tools do not require installation or the purchase and operation of specialized equipment like a drone. The tool is used in conjunction with the client’s mobile device to conduct simple, convenient, and effective inspections.

A downside to this tool is that you can only use it in locations where a client contact could physically take their mobile device. In other words, underwater and other unreachable machinery locations are not the best candidates for mobile device-based remote inspections.

Your Best Remote Video Inspection Platform for Factory Machinery

You need to consider four things when deciding what remote video platform is best for the factory machinery you are inspecting. First and foremost, you must consider your use case. Is the machinery you’re inspecting located in an area that is reachable by foot? How often does it require inspection? Questions like these and more can help you get a baseline of the features you will need from your remote video inspection platform.

Next, you need to consider cost. Some of these platforms, such as UAVs, can provide significant savings, but they will also require a considerable upfront investment. Make sure you are taking both of those elements into consideration. Third, you should consider flexibility. How much flexibility do you need in your inspection platform? Which platform listed will provide the kind of flexibility you need?

Lastly, you should consider convenience. Of course, when it comes to inspections, effectiveness is more important than convenience, but why wouldn’t you want to explore a platform that can provide both? A mobile device platform like Blitzz can provide quality inspections using nothing but an SMS message and a link to the calling environment. This is convenient for both your inspector and the client.

Schedule a demo today if you’re interested in seeing how Blitzz can simplify your remote video inspections for factory machinery!